Printed Circuit Boards

PCB Services

Printed circuit boards are at the very heart of today’s technological industry. They are used in every aspect of our lives, in telephones, amplifiers, computers, the automotive industry, medical equipment and almost every electronic appliance. With rapid advances in technology, electronic components must run faster and more efficiently, creating pressure to keep pace with customers’ demands in a changing market.

This is why PCB fabricators and Original Equipment Manufacturers (OEM) share the same concerns. Manufacturers want reliable, low cost printed circuit boards that meet even the most critical design requirements, including high frequencies, fast speeds and heat dispersion. As a supplier as well as a PCB assembler, BPC Electronics LTD is committed to providing quick production, on-time deliveries and competitive prices on consistently reliable circuit boards that users can depend on time and time again.

- LED PCB

- FLEXI RIGID PCB

- FR4 PCB

- COPPER CORE PCB

Our Services:

Our PCB fabrication facilities are UL+ISO-9001 certified, capable of producing single-sided PCBs, double-sided and multilayer circuit boards (up to 12 layer) using FR4, CEM-3 and polyimide materials. We can accept a wide variety of PCB design file formats including Gerber, Protel and AutoCAD.

Our PCB Services

We provide the following PCB services mentioned below:

-

LED PCB

BPC Electronics LTD has been working closely with manufacturers of LED based products for nearly a decade.

-

FLEXI RIGID PCB

Some printed circuit boards are designed to be very or slightly flexible, using polyimide film technology.

-

FR4 PCB

Over eighty percent of the PCBs we supply are made from FR-4 material. FR-4 is the grade designation for glass reinforced epoxy laminate PCBs.

-

COPPER CORE PCB

Our expertise is in producing reasonable priced, heavy copper PCBs for applications as diverse as power converters and welding equipment.

Effective solutions to complex interconnect designs

PCB & Electronics solutions

We aim to provide the best service to our customers, be it for a fast delivery 12 oz copper PCB , or a scheduled order for printed wire circuits. See below for more information on the types of printed circuit board we use.

PCB Services

Printed Circuit Board Services

We take pride in being able to provide competitive pricing together with the highest quality PCBs by producing them expediently at our offshore facilities. In our current economy cost and long term reliability are very important and with BPC Electronics LTD you have the ideal manufacturing partner.

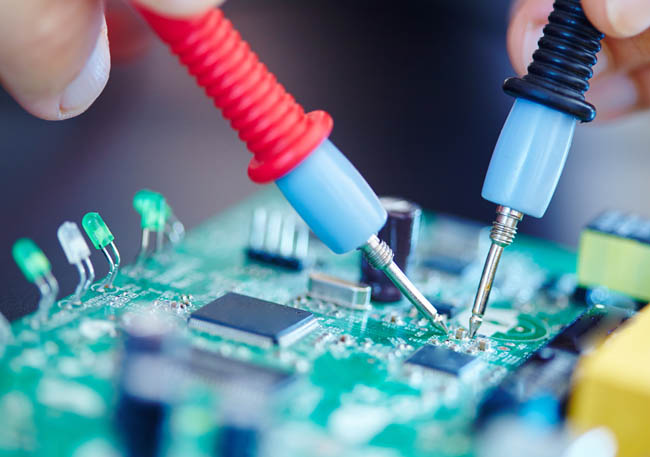

Your PCB Problems are our ChallengeServicesAt BPC we specialise in manufacturing our primary product: printed circuit boards up to 12 ounce copper. Because we do all processes under one roof, we are able to offer quality boards with first rate service. We have invested in state of the art machinery, which, together with our team of highly experienced engineers, make the Company an obvious first stop for assembly houses.

Standard and Specialist PCBsServicesAs a manufacturer, BPC Eelectronics are committed to providing quick production, on-time deliveries and competitive prices on consistently reliable boards that users can depend on time and time again. Our fabrication facilities are UL94VO+796+ISO 90001 certified, capable of producing standard single sided, double sided, multi layer, as well as a wide range of specialist finishes, such as metal core and metal backed printed circuits.

Offshore ManufacturingServicesBPC Electronics has wide experience of sourcing quality printed circuit boards from the Far East and maintains a strict policy of supervising and visiting its strategic partners on a regular basis. Customers can be assured that the same rigorous standards are maintained for all BPC products, whether manufactured in the UK or offshore. With a combined production capacity in excess of 10 million square metres per annum, volume production quantities are warmly welcomed.

24-Hour Turnaround on PCB’sServicesJust in time is an often quoted phrase: BPC makes it happen! Just send in your electronic data to us by fax or email and leave the rest to us. Single sided, multilayer and PTH boards can be sent out the next day subject to us receiving your details before 10am on the day prior to despatch. Please contact our sales team for more information.

SUBSTRATES

PCB Substrates information

With the ever changing demands placed upon the actual technical performance of the bare printed circuit board, it is important for BPC Electronics LTD to offer a full range of substrates to meet these requirements.

As the processing of all these materials has been fully integrated into the standard production system, BPC Electronics are able to offer them at competitive prices; the laminates available include:

- Rogers

- Taconic

- Panasonic

- Nanya

- Ventec

- Thermaggon

- Berquist

- Arlon

- Nelco

- Many more

-

TECHNOLOGY

-

CORE PRODUCTS

-

APPROVALS

-

KanBan – SUPPLY SOLUTIONS

-

QUALITY SYSTEMS

-

TECHNICAL OVERVIEW

STANDARD MANUFACTURING CAPABILITY – 1

Our PCB fabrication facilities are UL+ISO-9001 certified, capable of producing single-sided PCBs, double-sided and multilayer circuit boards (up to 12 layer) using FR4, CEM-3 and polyimide materials.

| LAMINATES | – | – |

|---|---|---|

| FR4 | (inc. Hi Tg, FR5, Polyimide, BT, Arlon, Rogers, Taconic, GE, Metal cored, Metal backed) | – |

| Maximum active board size | 584mm x 482mm | – |

STANDARD MANUFACTURING CAPABILITY – 2

Our PCB fabrication facilities are UL+ISO-9001 certified, capable of producing single-sided PCBs, double-sided and multilayer circuit boards (up to 12 layer) using FR4, CEM-3 and polyimide materials.

| TEST CAPABILITIES | STANDARD | ADVANCED |

|---|---|---|

| Minimum SMD Width | 0.015″ | 0.008″ |

| Minimum SMD Pitch | 0.020″ | 0.012″ |

| DRILLING | STANDARD | ADVANCED |

|---|---|---|

| Minimum Drill 1.6mm board | 0.35mm | 0.20mm |

| Minimum Drill 2.4-3.2mm board | 0.50mm | 0.35mm |

| Minimum Drill >3.2mm board | 0.70mm | 0.40mm |

| Minimum Drill Buried/Blind via | 0.35mm | 0.20mm |

| Minimum Drill 6.40mm | – | – |

| Aspect Ratio | 9.0:1 | 12.0:1 |

| PTH Diameter Tolerance +/- | 0.075mm | 0.025mm |

| Resist Types | STANDARD | ADVANCED |

|---|---|---|

| Photo imageable | – | – |

| OPSR | Red, Blue, Green, Black, White | Red, Blue, Green, Black, White |

| Lackwerke Peters | Red, Blue, Green, Black, White, Yellow | Red, Blue, Green, Black, White, Yellow |

| Technic LED White Minimum Diam | 0.006″ | 0.004″ |

| Registration tolerance +/- | 0.002″ | 0.001″ |

| SCREEN PRINT | STANDARD | ADVANCED |

|---|---|---|

| Minimum Text width | 0.008″ | 0.006″ |

| Legend | STANDARD | ADVANCED |

|---|---|---|

| Peters, Technic | White, Yellow, Blue, Black, Red | White, Yellow, Blue, Black, Red |

| Peelable | – | – |

| BOARD CONSTRUCTION | STANDARD | ADVANCED |

|---|---|---|

| Maximum Layer Count | 12 | 24 |

| Maximum Thickness | 4.7mm | 6.0mm |

| Tolerances +/- 1.6mm | 0.20mm | 0.10mm |

| 2.4mm | 0.20mm | 0.10mm |

| 3.2mm | 0.30mm | 0.15mm |

| >3.2mm | 0.30mm | 0.15mm |

| Minimum Core thickness | 0.01mm | 0.05mm |

| Buried/Blind Via | – | – |

| IMS | – | – |

|---|---|---|

| Dielectric Types | Thermaggon T-Preg, Ventec, VT4A1 | – |

| Dielectric Thickness | 0.004″, 0.006″, 0.010″, 0.012″ | – |

| Metal Substrates | Copper, Aluminium | – |

| Metal Substrates Thickness | 0.8, 1.0, 1.55, 2.0, 3.0 (also metal cored with PTH) | – |

| INNER LAYERS | STANDARD | ADVANCED |

|---|---|---|

| Minimum Annular ring (assuming no breakout) | 0.006 | 0.004″ |

| Minimum Track/Gap v. Copper Weight: | – | – |

| 0.50oz | 0.004″ | 0.003″ |

| 1.00oz | 0.005″ | 0.004″ |

| 2.00oz | 0.008″ | 0.006″ |

| 3.00oz | 0.012″ | 0.008″ |

| Copper Weights available | 0.5, 1, 2 | 3, 4, 6, 10 |

| FINISHES | – | – |

|---|---|---|

| Organic finishes | – | – |

| HASL | – | – |

| Pb Free HAL | – | – |

| Immersion Gold | – | – |

| Electrolytic Gold | – | – |

| Immersion Tin | – | – |

| Carbon Ink | – | – |

| Immersion Silver | – | – |

| Combination of above | – | – |

| OUTER LAYERS | STANDARD | ADVANCED |

|---|---|---|

| Minimum Annular ring (assuming no breakout) | 0.005″ | 0.003″ |

| Minimum Track/Gap v. Copper Weight: | – | – |

| 0.25oz | 0.004″ | 0.003″ |

| 0.50oz | 0.004″ | 0.003″ |

| 1.00oz | 0.005″ | 0.004″ |

| 2.00oz | 0.008″ | 0.006″ |

| Copper Weights available | 0.5, 1, 2 | 3, 4, 5, 6, 10+ |

| ROUT | STANDARD | ADVANCED |

|---|---|---|

| Rout | 0.15mm | 0.10mm |

| Scoring | 0.15mm | 0.15mm |

| Bevelling | ||

| C/sink | ||

| C/bore | ||

| Internal Cut-outs/Slots (Plated / Unplated) | ||

| Depth Milling | ||

| Minimum Router Diameter | 0.8mm | 0.6mm |